Product Description

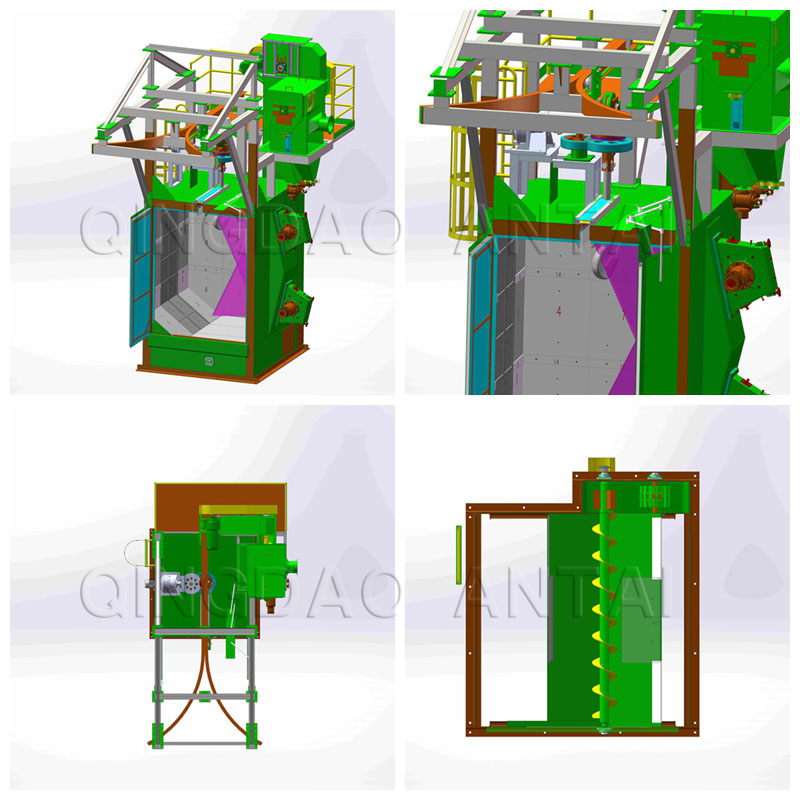

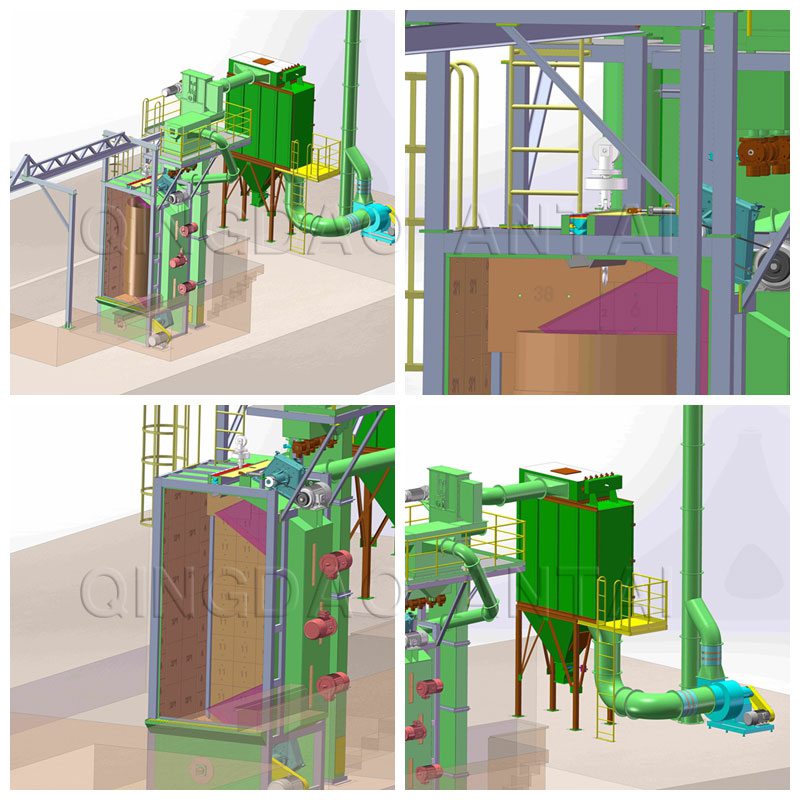

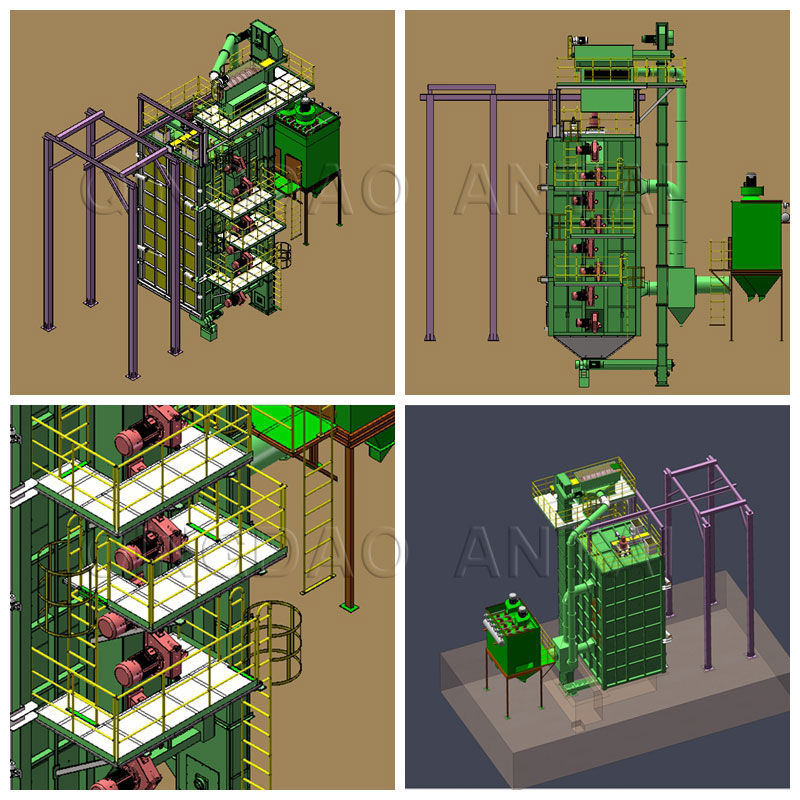

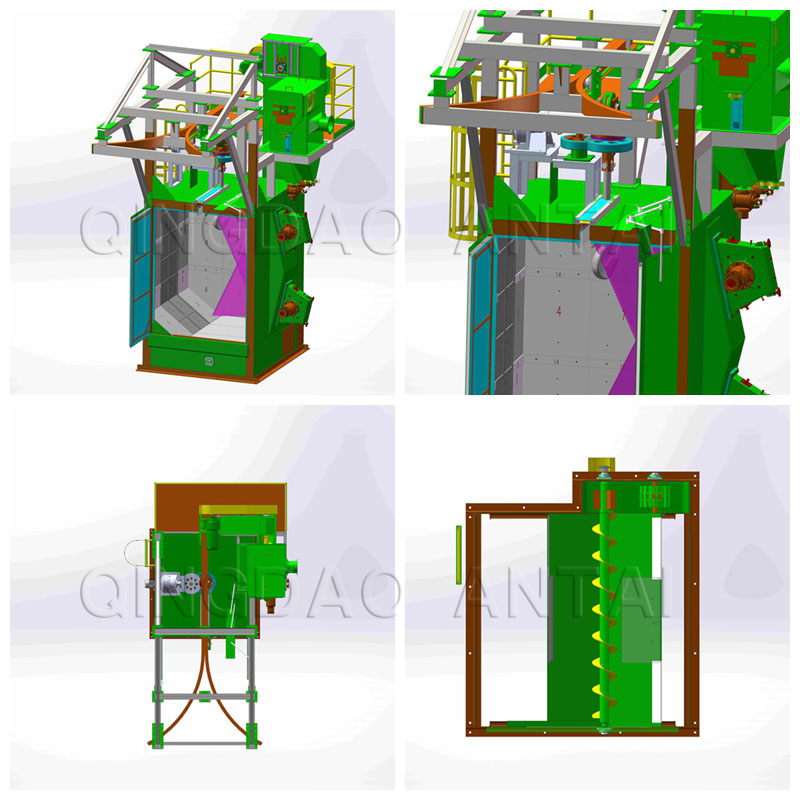

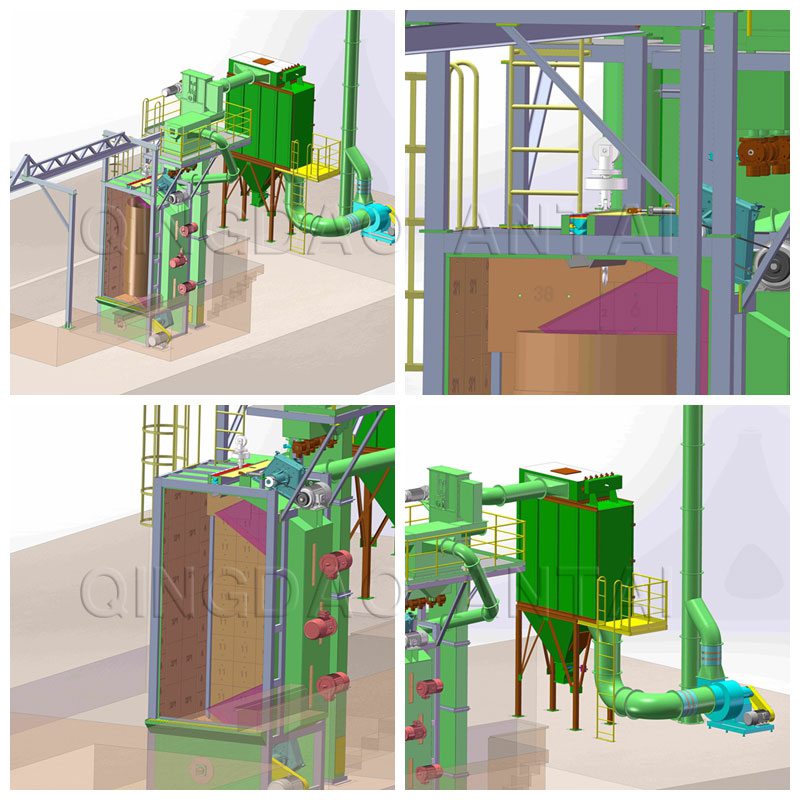

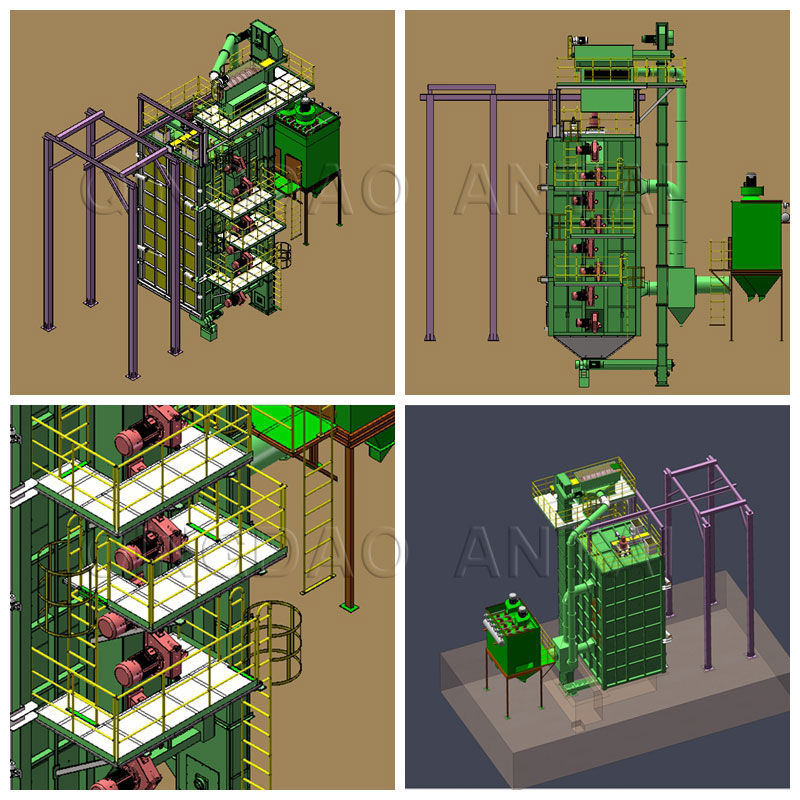

Hook shot blasting machines are designed to clean parts hanging from an overhead conveyor and used for castings or large parts that cannot be tumbled. We offer various designs including flow-through, Y-track, continuous or in-line blast designs. Some advantages to our designs include: low head room required, low initial investment, complete blast coverage without damaging parts.

The door of the overhead rail sand blasting machine is opened automatically and components are loaded on to the trolley mounted hanger. The door is then closed and the blast wheel unit is operated. The abrasive at high velocity falls upon the components on the rotating hanger, hanger rotates in both clockwise & Anti-clockwise direction and definite time period and blast clean the components. After the blast cleaning cycle is over, the blast wheel is shut off and door is opened automatically and hanger moves out for unloading of components. At the same time another hanger on the Y-track moves in for blasting purpose.

Range of Application

Desanding and final blast cleaning of castings (especially brittle parts and parts susceptible to impact damage)

Descaling of forgings or hardened parts

Derusting, roughening, finishing, sweeping

Shot peening for surface hardening

Deburring of plastic parts

Product Advantage

Compact design and easy operation

High blast cleaning performance

Economic abrasive consumption, reliable cleaning and dust collection

Broad range of machine types and options

Easy integration into production lines

High operational safety

Low maintenance, maintenance-friendly design

|

Model

|

Work piece cleaned

|

Load capacity

|

Blastng capacity

|

Ventilation capacity

|

Motor power

|

Outline dimensions

|

|

|

mm

|

kg

|

Kg/min

|

M3/h

|

kw

|

mm

|

|

Q376

|

Ø600*1100

|

500

|

2*120

|

5000

|

19

|

4429*2850*3443

|

|

Q378

|

Ø800*1500

|

1000

|

2*200

|

8000

|

32.5

|

4325*2660*5009

|

|

Q3710

|

Ø900*1600

|

1000

|

2*250

|

9000

|

36.55

|

5047*3850*5156

|

|

QD3710

|

Ø900*1600

|

1000

|

2*250

|

9000

|

39.65

|

5844*2742*5716

|

|

Q3720

|

Ø1400*2300

|

2000

|

3*250

|

15000

|

61.27

|

6110*3599*7842

|

|

Q3730

|

Ø1600*2300

|

3000

|

3*250

|

15000

|

64.4

|

7085*4650*8652

|

|

Q3750

|

Ø1800*2500

|

5000

|

4*250

|

18000

|

78.4

|

7062*5460*8652

|

|

Q3780

|

Ø2000*3000

|

8000

|

4*250

|

20000

|

81.5

|

8050*6400*8526

|

No.867 Century Avenue, Huangdao District, Qingdao, China

No.867 Century Avenue, Huangdao District, Qingdao, China 13361277779

13361277779 15908950799

15908950799 No.867 Century Avenue, Huangdao District, Qingdao, China

No.867 Century Avenue, Huangdao District, Qingdao, China 13361277779

13361277779 15908950799

15908950799